Seventh Axis

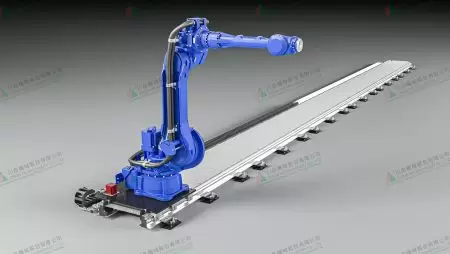

The 7th axis is a type of linear axis that can enable the robot to move along a fixed rail, increasing its working range and flexibility. The 7th axis can also integrate the robot arm with the production line more seamlessly, improving the efficiency and quality of the production process.

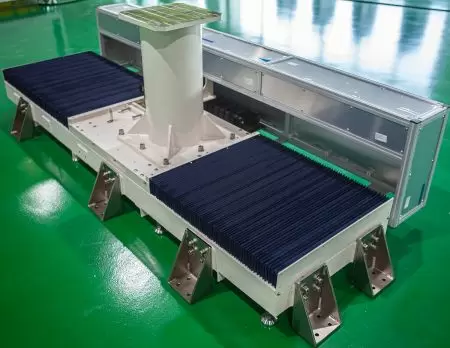

There are two modules options for the 7th axis:

Aluminum profile module: This module is made of aluminum profiles, which are lightweight, durable, and cost-effective. This module can be delivered quickly and easily installed.

Steel structure module: This module is made of steel structures, which are sturdy, precise, and heavy-duty. This module can handle higher loads and accuracy requirements.

Seventh axis system

The Seventh Axis is a linear axis that can move the robot along a fixed rail, connecting different...

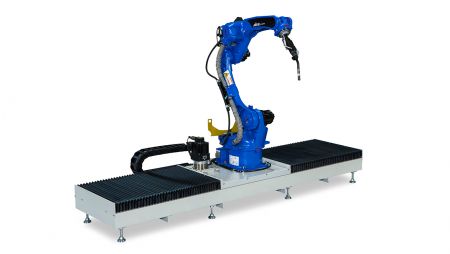

Details7th Axis robot transfer unit

Chain We Machinery's 7th Axis Robot Transfer Unit is a rack and pinion drive system that can easily...

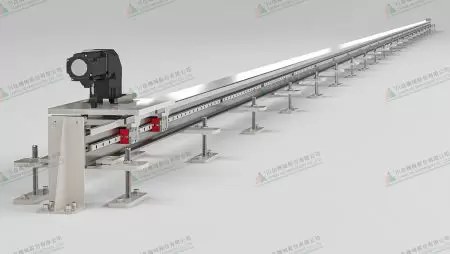

DetailsLinear track

Chain We’s Linear Track is a system that can greatly extend the work envelope and capabilities...

DetailsHow Can We Maximize Robot Coverage Across Extended Assembly Lines Without Multiple Robot Investments?

Our seventh axis linear rail system extends your existing robot's working range along fixed rails, enabling one robot to cover multiple workstations across your automotive assembly line. Choose our aluminum profile module for lightweight applications or steel structure module for heavy-duty automotive component handling. This cost-effective solution eliminates the need for multiple robot purchases while improving production flexibility and efficiency. Contact us for a customized assessment of your assembly line requirements.

Our comprehensive seventh axis solutions are manufactured in our state-of-the-art 14,500 square meter facility equipped with Industry 4.0 technology, ensuring precision engineering and reliable performance. Whether you require rapid deployment with our aluminum profile module or heavy-duty capability with our steel structure module, Chain We delivers end-to-end service from initial planning and design through manufacturing, installation, and ongoing maintenance support. The seventh axis system enhances your robotic investment by extending reach, improving cycle times, and enabling flexible production line configurations. Contact our automation specialists today to discover how our customized seventh axis linear rail systems can transform your factory automation and increase your competitive advantage in today's demanding manufacturing environment.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.