Seventh axis system | Chain We

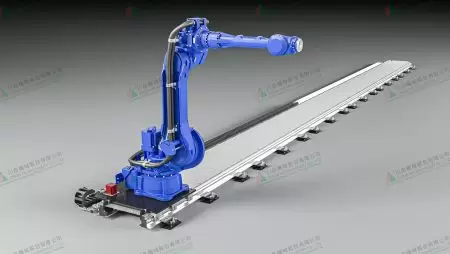

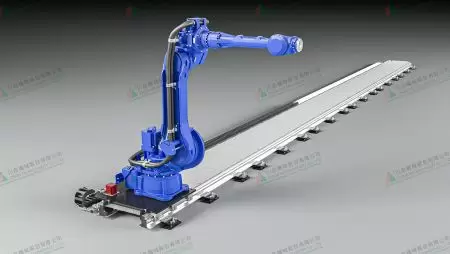

The Seventh Axis is a linear axis that can move the robot along a fixed rail, connecting different workstations or performing complex tasks. The Seventh Axis can enhance the flexibility and accuracy of the production line, especially for applications that require high precision and repeatability, such as welding.

The Seventh Axis can also provide the following benefits:

● Extended operating area: The Seventh Axis can transport multiple robots or heavy loads over long distances and to various workstations.

● Greater robotic output: The Seventh Axis can expand the work envelope, allowing smaller and cheaper robots to do the same work as larger robots.

● Flexibility: The Seventh Axis can handle different loads and speeds, depending on the production needs.

● Efficiency gains: The Seventh Axis can service more machines and processes with one robot, improving the productivity and quality of the production.

● Reduced capital costs: The Seventh Axis can save costs by using smaller robots, servicing more workstations, and increasing the range of motion.

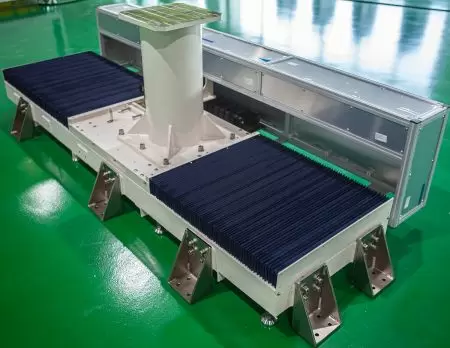

ChainWe's Seventh Axis shuttle system is a type of linear axis that can move any type of robot weighing up to 1500 Kg and with a stroke length of up to 30m. ChainWe's Seventh Axis shuttle system is a reliable and cost-effective solution for flexible production lines. Explore conveyor products across Chain We categories to match your line or warehouse needs. Review product pages for functions, applications, and integration notes. Contact Chain We for configuration guidance and quotations.

Seventh axis system

Linear Track for robot, robot linear track, Robot Linear Rail System, 7th Axis Rack and Pinion Track, robot transfer unit, RTU

The Seventh Axis is a linear axis that can move the robot along a fixed rail, connecting different workstations or performing complex tasks. The Seventh Axis can enhance the flexibility and accuracy of the production line, especially for applications that require high precision and repeatability, such as welding.

The Seventh Axis can also provide the following benefits:

● Extended operating area: The Seventh Axis can transport multiple robots or heavy loads over long distances and to various workstations.

● Greater robotic output: The Seventh Axis can expand the work envelope, allowing smaller and cheaper robots to do the same work as larger robots.

● Flexibility: The Seventh Axis can handle different loads and speeds, depending on the production needs.

● Efficiency gains: The Seventh Axis can service more machines and processes with one robot, improving the productivity and quality of the production.

● Reduced capital costs: The Seventh Axis can save costs by using smaller robots, servicing more workstations, and increasing the range of motion.

ChainWe's Seventh Axis shuttle system is a type of linear axis that can move any type of robot weighing up to 1500 Kg and with a stroke length of up to 30m. ChainWe's Seventh Axis shuttle system is a reliable and cost-effective solution for flexible production lines.

- Video

- Related Products

7th Axis robot transfer unit

Chain We Machinery's 7th Axis Robot Transfer Unit is a rack and pinion drive system that can easily...

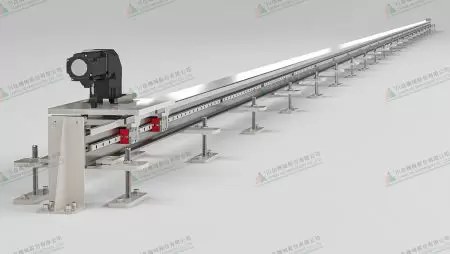

DetailsLinear track

Chain We’s Linear Track is a system that can greatly extend the work envelope and capabilities...

DetailsSeventh axis linear module

Seventh axis linear module of the Robotic Arm endows the original six-axis Robot with the seventh-axis...

Details

Seventh axis system | Chain We

Need higher throughput and smoother material flow? Chain We builds Seventh axis system to match your load, line speed, and layout—supporting stable transfer, controlled accumulation, and easier integration with sensors and PLC control.

Since 1988, Chain We in Taiwan has delivered customized conveyor systems and automation solutions, including assembly line conveyors, ASRS conveying equipment, robotic palletizing integration, pallet dispensers, and project-based system engineering.

Typical applications include semiconductor and electronics lines, panel manufacturing, logistics and automated warehouses, plus medical, food, paper, and automotive operations—helping teams reduce manual handling and keep production running consistently.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.