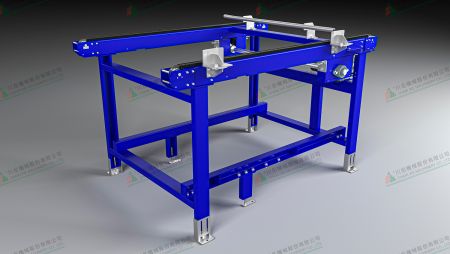

Chain Conveyor for pallet

Chain Conveyors is the ultimate solution for Pallet Handling.

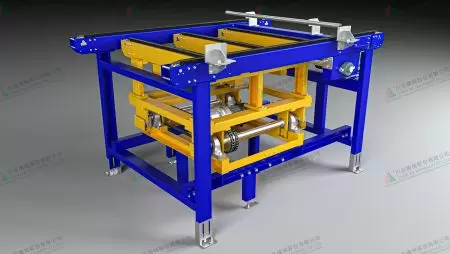

Chain conveyors are composed of modular sections that can be joined together to form any layout you require. They are available in medium duty and heavy duty models, depending on the weight of the loaded pallets. They can also be equipped with double or triple chains, depending on the width and stability of the pallets. Chain conveyors can handle pallets made of timber, recycled materials, plastic or metal, and can accommodate different standard pallet sizes.

If you are looking for a reliable and efficient way to handle pallets in your warehouse, conveying or palletizing system, you could consider using chain conveyors. Chain conveyors are devices that use chains to move pallets in any orientation, allowing you to load and unload them by forklift more easily. Chain conveyors can also integrated with other pallet handling equipment, such as pallet roller conveyors, palletizers, pallet turntables, pallet stackers and pallet destackers, to create a complete pallet handling system.

Chain conveyors have several advantages over other types of conveyors, such as:

- They can move pallets in any direction, parallel or perpendicular to the conveyor line, giving you more flexibility in your floor space and layout design.

- They can lift or lower pallets from one conveyor to another, or to a workstation area, using pneumatic or electric actuators, reducing manual labor and handling costs.

- They can be controlled by sensors, switches, or PLCs, depending on the level of automation and integration you need, improving the efficiency and accuracy of your pallet handling system.

You can select the most suitable chain conveyor model, type, and style for your application. For example, if you need to handle heavy pallets up to 1,000 kgs, you might want to use a heavy-duty triple chain conveyor. If you need to move pallets in different directions, you might want to use a through the rail type chain conveyor. If you need to operate the chain conveyor in continuous mode, you might want to use a sensor or a PLC to control it.

If you are not sure which chain conveyor is best for you, you can contact us for professional advice and guidance. We have over 30 years of experience in providing high-quality chain conveyors and pallet handling equipment for various industries and applications. We can provide you with a customized chain conveyor solution that meets your specific requirements and expectations.

Contact us today to find out more about chain conveyors and how they can help you improve your pallet handling system. We are happy to answer any questions you might have and provide you with the best chain conveyor solution for your business.

- Related Products

Chain conveyor system

The chain conveyor module is designed to meet different configurations and layouts, making...

DetailsChain transfer conveyor

Moving Heavy Loads and Pallets with Ease: The Benefits of Chain Transfer conveyor in Material...

DetailsAutomation machine for packaging line

Our packaging automation conveyor solution covers a range of processes, including conveying,...

Details

How Can We Maximize Warehouse Floor Space While Improving Pallet Throughput?

Our modular chain conveyors move pallets in any direction—parallel or perpendicular—allowing you to optimize floor space utilization while handling up to 1,000 kg loads. With flexible layout configurations and seamless forklift integration, you can increase throughput by up to 40% compared to traditional systems. Contact us for a customized layout assessment and discover how our 30+ years of expertise can transform your distribution center efficiency.

With over 30 years of experience in customized conveying systems, we deliver comprehensive pallet handling solutions that integrate seamlessly with roller conveyors, palletizers, pallet turntables, stackers, and destackers. Our chain conveyors feature pneumatic or electric actuators for lifting and lowering pallets between conveyor levels or workstation areas, significantly reducing manual labor and handling costs. Control options range from sensors and switches to full PLC integration, depending on your automation requirements. Whether you need continuous operation mode for high-throughput applications or precise positioning for forklift loading and unloading, our engineering team provides professional guidance to select the optimal chain conveyor model, type, and style for your specific application, backed by comprehensive support from planning and design through installation and ongoing maintenance.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.