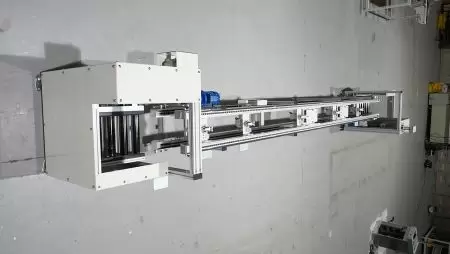

Double plus chain conveyor

Double speed chain conveyor, Free Flow conveyor, conveyor chains with rollers

The Double Plus Chain Conveyor is a rapid, flexible solution for material handling in assembly and processing lines, surpassing conventional single-speed conveyors. It offers faster, smoother handling, a modular design, and efficient space use. Tailored to the weight and accumulation needs of your materials, it's perfect for transport in production lines. Featuring a stopper mechanism, it enables material accumulation at workstations, enhancing safety and quality control.

For more details on this innovative conveyor, feel free to contact us.

Benefits

The double plus chain conveyor offers many benefits over the conventional single speed conveyor, such as:

• Faster and smoother material handling: The double plus chain conveyor can achieve a higher speed ratio between the chain and the pallets, up to 2.5 times. This means that the pallets can run faster and smoother, reducing the cycle time and increasing the throughput.

• Flexible and modular design: The double plus chain conveyor is constructed in aluminium extrusion for easy setup and layout. You can customize the conveyor length, width, height, and shape according to your needs. You can also add accessories such as sensors, guides, or covers to suit your application.

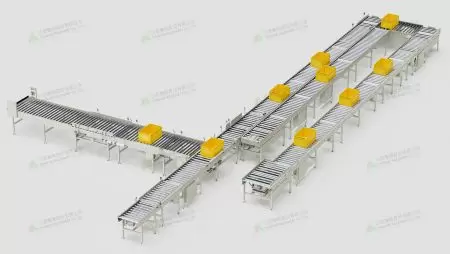

• Compact and efficient space utilization: The double plus chain conveyor can save space by using compact lifters, transfers, and diverters. For example, you can install a compact lifter at the end of the line for pallet return conveyor systems, or a lift and transfer unit (LTU) for cross transfer to adjacent conveyor lines for a closed loop conveyor system. You can also use electrical or pneumatic controlled stoppers to separate product or pallets for assembly process.

Features

The double plus chain conveyor is selected according to the weight of the conveyed object and the amount of accumulation.

• The size and shape of the pallets or trays: The pallets or trays should match the size and shape of the conveyed objects, and should be compatible with the chain and the conveyor rails. The pallets or trays should also have a flat and smooth bottom surface to ensure a stable contact with the chain.

• The load capacity and speed of the conveyor: The load capacity and speed of the conveyor depend on the weight and size of the conveyed objects, the number and spacing of the pallets or trays, and the friction between the chain and the conveyor rails.

• The layout and configuration of the conveyor: The layout and configuration of the conveyor depend on the available space, the desired shape and direction of the conveyor, and the accessories and components that you want to add. You need to plan the layout and configuration of the conveyor based on these factors, and choose the suitable conveyor rails, supports, joints, and connectors.

- Related Products

Free Flow conveyor system

The Free Flow Conveyor System, an advanced solution from Chain We Machinery, is ideal for precise...

DetailsDouble speed chain conveyor

Chain We's Double Speed Chain Conveyor is an innovative, high-speed solution for object transportation...

DetailsConveyor line for logistics box

Our automated carton & boxes conveyor system & equipment covers a range of processes, including...

Details

How Can We Reduce Assembly Line Cycle Time While Maintaining Quality Control?

Our Double Plus Chain Conveyor achieves up to 2.5 times faster material handling than conventional conveyors while incorporating stopper mechanisms at workstations for precise quality control. This combination reduces your cycle time and increases throughput without compromising safety or inspection standards. Contact us to discover how our 30+ years of automotive assembly line expertise can optimize your production efficiency.

Designed for compact and efficient space utilization, our double plus chain conveyor integrates seamlessly with compact lifters, transfers, and diverters for closed-loop conveyor systems. The system is selected according to the weight of conveyed objects and accumulation needs, ensuring optimal performance across diverse applications including factory assembly lines, automatic assembly lines, and smart logistics environments. Featuring electrical or pneumatic controlled stoppers for process separation, customizable accessories such as sensors and guides, and compatibility with lift and transfer units (LTU) for cross-transfer operations, this innovative conveyor solution provides the flexibility and reliability demanded by modern automated production facilities.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.