Vertical reciprocating elevator | Chain We

Chain We Machinery's Vertical Reciprocating Elevator: A Space-Saving and Cost-Effective Solution for Vertical Material Handling

If you need to transport boxes, containers, trays, packages, bags, barrels, kegs, pallets, or other items between different floor levels, you may want to consider Chain We Machinery's vertical reciprocating elevator. This is a type of vertical lift that can elevate and lower materials in multi-level applications, such as factories, warehouses, distribution facilities, industrial plants, institutions, or anywhere that products or supplies need to be moved from one level to another.

Unlike elevators, vertical reciprocating elevators are designed for material handling only and can carry loads from 1 ton to 10 tons. They have adjustable table sizes and can reach up to 6 stops and 30 meters in height. Vertical reciprocating elevators can be hydraulic or mechanical, depending on the lifting capacity and lifespan you need.

Vertical reciprocating elevators are a safe, economical, and convenient way to raise and lower materials. They save valuable floor space compared to incline conveyors or spiral type conveyors, and they are more efficient and secure than fork lifts. They also reduce the risk of injury and damage to the materials and the workers.

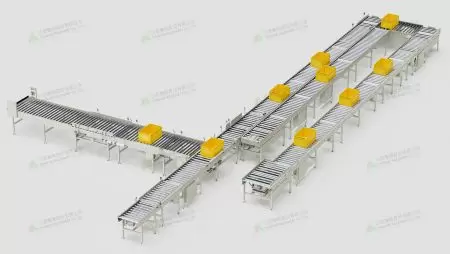

Chain We Machinery's vertical reciprocating elevator can be customized according to your specific needs and requirements. You can choose from different configurations with multiple carrier conveyors, which are available with belt, roller, or chain conveyor systems. The conveyor systems can be one-directional, two-, or three-directional, depending on the direction of the material flow. The carrying frames and the lift carriages are designed to ensure smooth, stable, and gentle transport of your materials.

Chain We Machinery has been in the business of vertical material handling for over 30 years. We will design a customized vertical lift product tailored to your needs. Our focus has always been on safety and advanced technology, and creating solutions for specific vertical material handling problems.

If you are interested in Chain We Machinery's vertical reciprocating elevator, please contact us today for a quote and consultation. We will be happy to answer any questions you may have and provide you with the best solution for your vertical material handling needs. Explore conveyor products across Chain We categories to match your line or warehouse needs. Review product pages for functions, applications, and integration notes. Contact Chain We for configuration guidance and quotations.

Vertical reciprocating elevator

Vertical reciprocating lift

Chain We Machinery's Vertical Reciprocating Elevator: A Space-Saving and Cost-Effective Solution for Vertical Material Handling

If you need to transport boxes, containers, trays, packages, bags, barrels, kegs, pallets, or other items between different floor levels, you may want to consider Chain We Machinery's vertical reciprocating elevator. This is a type of vertical lift that can elevate and lower materials in multi-level applications, such as factories, warehouses, distribution facilities, industrial plants, institutions, or anywhere that products or supplies need to be moved from one level to another.

Unlike elevators, vertical reciprocating elevators are designed for material handling only and can carry loads from 1 ton to 10 tons. They have adjustable table sizes and can reach up to 6 stops and 30 meters in height. Vertical reciprocating elevators can be hydraulic or mechanical, depending on the lifting capacity and lifespan you need.

Vertical reciprocating elevators are a safe, economical, and convenient way to raise and lower materials. They save valuable floor space compared to incline conveyors or spiral type conveyors, and they are more efficient and secure than fork lifts. They also reduce the risk of injury and damage to the materials and the workers.

Chain We Machinery's vertical reciprocating elevator can be customized according to your specific needs and requirements. You can choose from different configurations with multiple carrier conveyors, which are available with belt, roller, or chain conveyor systems. The conveyor systems can be one-directional, two-, or three-directional, depending on the direction of the material flow. The carrying frames and the lift carriages are designed to ensure smooth, stable, and gentle transport of your materials.

Chain We Machinery has been in the business of vertical material handling for over 30 years. We will design a customized vertical lift product tailored to your needs. Our focus has always been on safety and advanced technology, and creating solutions for specific vertical material handling problems.

If you are interested in Chain We Machinery's vertical reciprocating elevator, please contact us today for a quote and consultation. We will be happy to answer any questions you may have and provide you with the best solution for your vertical material handling needs.

Benefits

Benefits of Using a Vertical Reciprocating Elevator

A VRE can offer you many benefits for your material handling needs, such as:

- It can be loaded with pallet goods and material boxes, cartons, etc. The lifting stroke can customize according to your demands.

- It is suitable for vertical conveying on multiple floors. It can be integrated with a conveyor system or an automated guided vehicle (AGV) for seamless material flow, reducing labor and increasing efficiency.

- It is safe and reliable, with multiple safety features such as overload protection, emergency stop, interlocking doors, etc. It also complies with the relevant safety standards and regulations.

- It is easy to install and maintain, with minimal civil work and low power consumption. It also has a long service life and low noise level.

- Video

- Related Products

Vertical reciprocating conveyor

Chain We's Vertical reciprocating conveyor for Clean Room: A Dust-Free and Sterile Solution...

DetailsLift for AGV Docking

Lift for AGV Docking can enable automated material handling between different floor levels...

DetailsConveyor line for logistics box

Our automated carton & boxes conveyor system & equipment covers a range of processes, including...

Details

Vertical reciprocating elevator | Chain We

Need higher throughput and smoother material flow? Chain We builds Vertical reciprocating elevator to match your load, line speed, and layout—supporting stable transfer, controlled accumulation, and easier integration with sensors and PLC control.

Since 1988, Chain We in Taiwan has delivered customized conveyor systems and automation solutions, including assembly line conveyors, ASRS conveying equipment, robotic palletizing integration, pallet dispensers, and project-based system engineering.

Typical applications include semiconductor and electronics lines, panel manufacturing, logistics and automated warehouses, plus medical, food, paper, and automotive operations—helping teams reduce manual handling and keep production running consistently.

One-stop automation service

Comprehensive automation service from planning, design, manufacturing, installation, and ongoing maintenance and support.

Customized Solutions

Expert in automatic conveying systems for various industries. 30+ years of experience in Taiwan and worldwide.

Various conveyors

Various and customized conveying systems for your needs and serve a wide range of industries.